Case studies

Harris Gerrard Academy (DA London)

- Refurbishment of x6 AHU including motor replacement with 1 year maintenance contract

- Heating and cooling coil replacement x1 AHU

- Toilet extract system installation and other fans upgraded or repaired

- Provided updated drawings of mechanical works on completion

- Commissioning of ventilation system on completion of works

- X1 Chiller service with minor repairs

- Removal and replacement of several existing ductwork sections with new lagging for ongoing roof floor repairs

- HTW and CHW pipework and water quality servicing including a full system flush

- Biomass and Gas fired Boiler servicing

This project was initially an external AHU refurbishment project, including motor replacements and filter channel repairs. We also coordinated ductwork removal and replacement in partnership with the appointed roof flooring contractor. However, once our initial appraisal of the mechanical works were concluded, it was clear that several areas of the school services mechanics had been neglected, which was contributing to the poor performance of the school heating system. AirWizard provided additional support in identifying and fixing these issues.

This included internal clogging in pipework and sieves which was affecting the AHU heating performance. Coil damage, leakage and general bacteria build up. In one case the replacement of both heating and cooling coils was required with new pipework also fitted. All equipment provided, including new fans and a toilet extract system, were tested and commissioned on completion to the customers satisfaction. We also provided updated roof drawings of the schools services, as existing drawings were incorrect in several areas and missing important detail which we rectified.

|

|

| |||

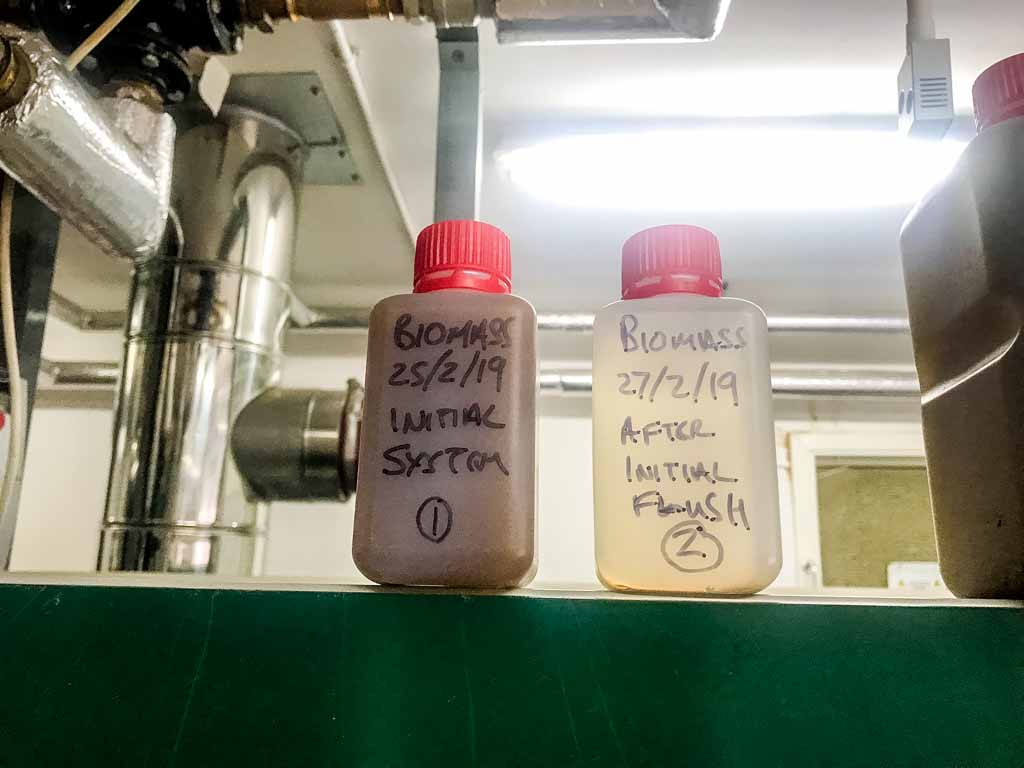

| Water quality before and after our works with examples of waste build up found in sieves | |||||

|

| ||||

| Example of ductwork to be removed | Conducting ductwork modifications | ||||

|

| ||||

| Coils on works completion | Coils pre commencement of works | ||||

Wimbledon No.1 Court (SW London)

- Wimbledon Lawn Tennis /Skanska/ Aermec

- Installation of 12 AHU

- Leakage Testing of AHU

This project involved delivery to site of 12 large (12 m3/s) AHUs which arrived in several sections to be lifted onto the three relevant roof areas for final positioning by AirWizard. We were required to build each unit in-situ, connect and seal modular sections, and complete all internal wiring to a common external point. Within each phase we supervised crane deployment of unit sections to confirm these were landed in the correct order for our works program. Each phase had a time critical window for completion (which we met on each occasion) due to the site and all facilities being removed at key periods leading up to The Wimbledon event.

We were also required to test each unit to British DW143 leakage standards, which involved our engineers sealing the ends of each unit with blanking plates and providing test equipment to conduct a witness test, as well as providing a comprehensive report on the results found. All units we tested passed at a higher standard then was required, which was both a credit to the quality of the unit manufactured, as well as our ability to build the units to the same standard as the factory on site. A sample of units were tested at the factory to provide a base level of quality required on site as the client placed a high importance on this aspect of the project.

|

|

| |||

| AirWizard staff providing finishing touches to AHU installation | |||||

Becket House (SW London)

Earnest Young/GBE/ Moducel Coleman Units

- General service and maintenance of 6 AHUs

- Remove and upgrade to higher efficiency fans on 5 AHUs

- Remove and replace damaged AV mounts with superior mounts.

- 12 month service contract

For this project we were required to inspect and provide feedback with recommendations for the servicing of the AHUs. A new tenant was taking over the buildings, who were interested in a balance between minimizing capital expenditure, while maximizing energy saving on running costs. We recommended servicing of the AHU components such as cleaning of coils, refitting new filter frames and door seals, among several other items we highlighted in this area. Air Wizard also recommended the replacement of belt and pulley fans for high efficiency EC alternatives on all the units.

We also discovered through our investigation, several vibration related issues which were being caused by poorly fitted AV mounts on one of the existing fan sections which we were not instructed to replace due to its constricted positioning. Our solution was to remove the faulty AV mounts without removing the fan, and replace with higher grade AV mounts that compensated for the lateral movement being generated by the fan. This eliminated the vibration issue which was causing structural damage to the casing in the fan section and its connections to the ductwork of this specific unit.

We provided a 12 month service agreement where we attended site a year later to conduct a service and check up on the operation of the unit.

|

|

|

|

| New Fan installation | Fan crane lift | Before and after our corrosion treatment to AHU | |

|

|

|

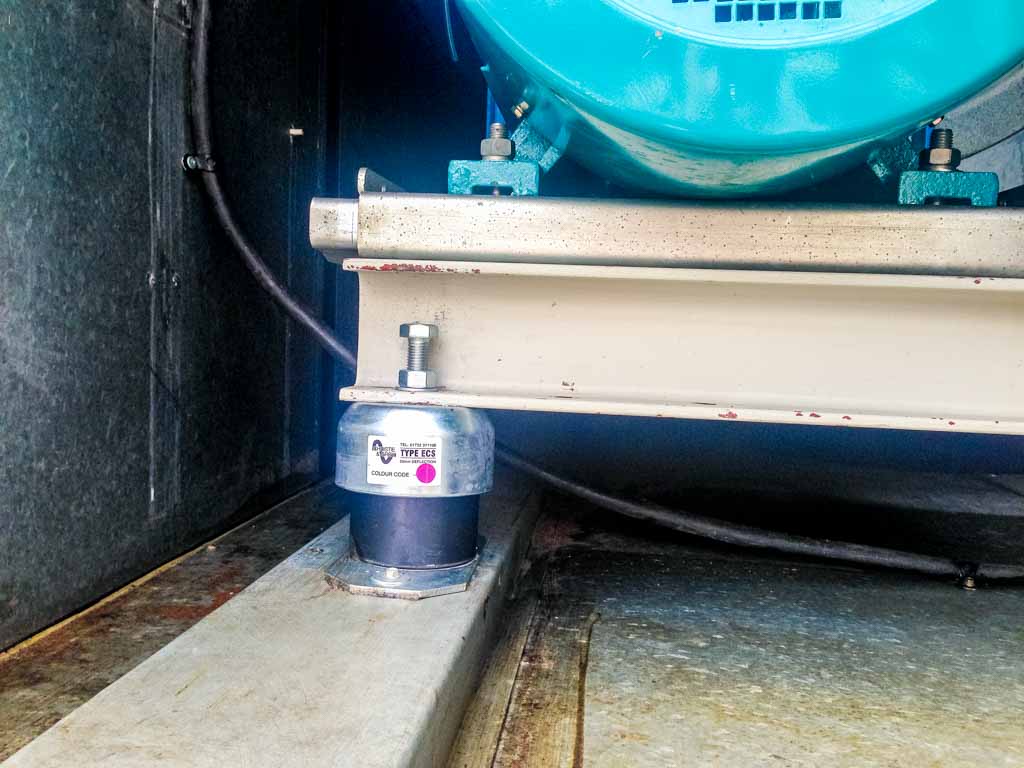

| New fan flexi connections | Faulty AV mount | Installation of new AV mount |

Kew Bridge (TW London)

Welfare Wing - St Georges / Specific interiors

- Supply and installation of extract system

- Fix faulty duct work in various locations

- Fix faulty HRU and connecting ductwork

- Replace dampers on central plant

- Install smoke extract system

On this project we were asked to supply and install a new extract system serving a main staff lunch room and connecting toilets and shower facilities. This included all ductwork, fans grilles and diffusors including bespoke ductwork and fittings in hard to reach locations. We also repaired a faulty heat recovery unit and made several minor modifications to various ductwork sections within the buildings apartment and office areas. We replaced faulty dampers and actuators, which also included the installation of a smoke extract system on another site linked to our customer, as part of our overall service to this client.

|

|

| AHU dampers being removed | Smoke fans after installation |

|

|

| Examples of ductwork and extract system installation | |

Beckett House

On this project our client had 6 large supply air handling units which required modernisation . The building was being handed over to a new tenant and we were asked to inspect and report on all the current condition of the AHUs and make our recommendations on maximising the existing performance and life span. Improving the efficiency and therefore reducing running costs was also a requirement.

Through our investigations we concluded that all units required a thorough hygienic clean, as there were signs of deep lime scale water stains as well as areas of rust ingress in several sections of the units. In discussions with our client four of the six fans were recommended for replacemen,t as new fans would improve efficiency by 18% and noise by 4dba per fan. This also had the added benefit of future proofing the units for increases in performance inline with the increase in demand within the building as a whole.

The remaining two fans had vibration issues which required new anti vibration mounts. The existing mounts were not dealing with the horizontal vibration therefore we replaced with a lateral load bearing AV mount.

Additional List of Projects

Below is a sample list of several other projects we have conducted. We can issue a more exhaustive list if required.

Watchmaker Building (EC London) - FCU repairs and ductwork and pipework replacement and coil leakage testing

No.1 St James st (WC London) - AHU service, leakage test, fan upgrade and ductwork replacement and repair.

24 King William st (EC London) - AHU flat pack installation of DX integrated heat pump within AHU system

National College of High Speed Rail (Birmingham) - 3 AHU installations and leakage testing

Liverpool Life Science - (Liverpool) - x2 AHU installations and ductwork integration

Bradfield Centre (Bradford) - AHU installation and on site leakage testing

Furness House (WC London) - Flat pack install of AHU and connecting ductwork

Royal Lancaster Hotel (W2 London) - Additional AHU fan and coil upgrade including general service. This involved pipework removal and reconnection with controls installation and commissioning.

HSBC Pall Mall branch (EC London) - AHU fan upgrade and service with ductwork modifications

Houses of Parliament (SW London) - AHU x7 installation

Bell Farm Primary School (KT London) - Removal, repair, install and commission x12 AC units

Additional information on any of the projects listed can be provided on request.